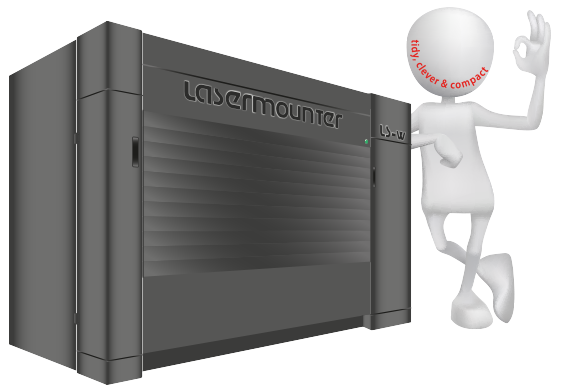

“Lasermounter LS-w” is totally new from the ground up. Having looked at the benefits of the existing Lasermounter system, we have created a semi automatic machine that allows the registration of plates with two x-y keys.

Servos used throughout - computer controlled”

I’m 1.48 m High, 2.15m wide, 0 .72m deep and weigh 1200kg

ph +64 7 824 7143

mob +64 21 521 586

address 525 Waingaro Road, RD1

Ngaruawahia 3793, New Zealand

email info@lasermounter.com

consult@flexolink.com